Thank you for Subscribing to Electrical Business Review Weekly Brief

Electrical Business Review: Specials Magazine

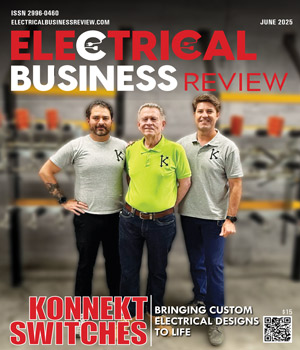

For over 25 years, a family-run powerhouse has been flipping the switch on what’s possible in the medium-voltage switchgear sector. Born from a father’s vision and led by the next generation, Konnekt Switches stands as a driving force of precision and custom switchgear. Its customer-focused business ethos enabled Konnekt to evolve into a trusted name in electrical switches and power distribution solutions. “Our strength is engineering custom solutions and premium voltage switches tailored to specialized needs. If an engineer can envision it, we can build it,” says Oscar de la Fuente, VP of sales and engineering. Konnekt’s reputation comes from its medium-voltage switches, handling 5kV to 38kV and 600A to 6,000A. These switches ensure efficient, reliable power distribution. The company isn’t just about making switches—it’s about making power systems safer, smarter, and more reliable. Its disconnect switches enable seamless, secure maintenance, while its grounding switches go beyond protection, safely redirecting excess current to prevent damage and downtime. For high-power applications, Konnekt’s high-current special switches withstand extreme loads 6000AMP and short-circuit ratings up to 65kA, delivering the durability and performance industries demand. Beyond tough equipment, adaptability is the key. The company specializes in modifying and retrofitting switches, helping customers upgrade outdated components without major system overhauls. This flexibility cuts costs, reduces downtime and keeps operations running. Unlike off-the-shelf products, Konnekt’s custom-built solutions align precisely with business needs. It collaborates with engineering firms, system integrators and capacitor bank manufacturers to tailor products. Once the switchgear is ready, the clients receive a video demonstration and detailed drawings for final approval before shipment. In some cases, customers want to inspect a prototype to ensure it meets their specific requirements. The company then allows them to visit the facility, review the prototype, and provide modification feedback.

Top Electrical Contractor Service in New Jersey 2025

When homeowners call for a repair—a leaky pipe, a faulty outlet or a broken AC—they’re usually trying to fix one visible issue. But it’s rarely isolated. Home systems are connected. Plumbing works alongside HVAC. Electrical underpins almost everything. And attic insulation, often overlooked, affects both temperature control and energy efficiency. Yet most service providers are built around a single trade. So, even a straightforward HVAC installation can require calling in an outside electrician. That means longer timelines, multiple crews and uneven quality—all because responsibility is fragmented. Krise Services is built to solve this fragmentation. By offering plumbing, HVAC, electrical, water treatment and insulation all under one roof, Krise ensures every piece connects seamlessly. There is no waiting on third-party vendors or watching accountability blur between contractors. It results in a tighter workflow, better communication between trades and more reliable outcomes for the homeowner. Exceptional electrical work forms the core of this model. Rather than considering it as a good-to-have add-on skill in the list, Krise made it foundational from day one. CEO Greg Guth co-owned a trade school to train technicians to Krise’s own standards, ensuring every team member is grounded in a culture of safety, skill and customer-first thinking. On joining Krise’s workforce, these professionals grow with the company and carry that consistency into every job. That’s how Krise delivers what most homeowners want: fair pricing, dependable service and the confidence that the job will be done right—end to end, without compromise. “Every job is treated not as a transaction, but as the beginning of a long-term relationship, one built on trust and technical clarity,” says Guth. And that clarity starts from the very first call. When a client reaches out, the process begins with a thorough in-home assessment—one that looks not just at the electrical system, but at plumbing, HVAC and insulation as well. The goal isn’t just to fix what’s broken. It’s to spot issues before they turn into bigger problems. That way, clients avoid future disruptions and know exactly what they’re working with.

CXO INSIGHTS

Driving Sustainable Energy Solutions for a Greener Future

Jason Colbenson, Senior Quality Assurance Specialist, Dairyland Power Cooperative

Benefits Of Installing An Ev Charger At Home

Tim Davis, Electrical Manager, F.H. Furr Plumbing, Heating, Air Conditioning, & Electrical

The Role of Electrical Testing in Commercial Property

Clara Müller, Director Of Testing And Quality Assurance, ALS Limited

World Class Manufacturing Plant and Operational Excellence

Laurent Tarnaud, Director of Manufacturing, Trojan Batteries for Lithium Product

The Evolution and Integration of Renewable Energy

Jim Helvig, P.E., Vice President of Operations, Dashiell Corporation

Prefabrication, Modelling, And The Modular Future Of Electrical And Intelligent Transportation Systems In Construction

Daniel Cole, PMP, Senior Project Program Manager, Aldridge Electric, Inc

Driving Customer-Centric Innovation in the Data Center Industry

Jorge Quintana, Head of Sales North America, Anord Mardix

IN FOCUS

EDITORIAL

Driving Business Performance through Smarter Practices

Manufacturers of medium voltage switches are responding to these demands by rethinking their product lines to better serve modern construction and system design realities. Equipment today needs to do more than just function. It must be installed cleanly, integrated with increasingly digital control systems and operated without complications in environments where downtime carries a real cost. Across the board, the focus is shifting toward products that are easier to maintain, more adaptable in the field and durable in the long term, especially in settings where load conditions and safety standards are nonnegotiable.

Contracting teams in this space feel the same pressure to meet rising expectations. On many jobs, the timeline is tighter, technical requirements are steeper and room for improvisation has disappeared. Instead of relying on experience alone, contractors are turning to sharper planning, better coordination with suppliers and a stronger grasp of the systems they’re implementing.

When product design and field execution align well, the result improves over time. A strong connection between manufacturer and contractor leads to fewer callbacks, seamless commissioning and systems that perform consistently without requiring extra adjustment.

In this edition of Electrical Business Review, we explore recent developments in medium-voltage switch manufacturing and electrical contractor services and how they are shaping project outcomes by aligning product design with installation realities.

We hope this edition of the Electrical Business Review helps you find the right partner for your business requirements.